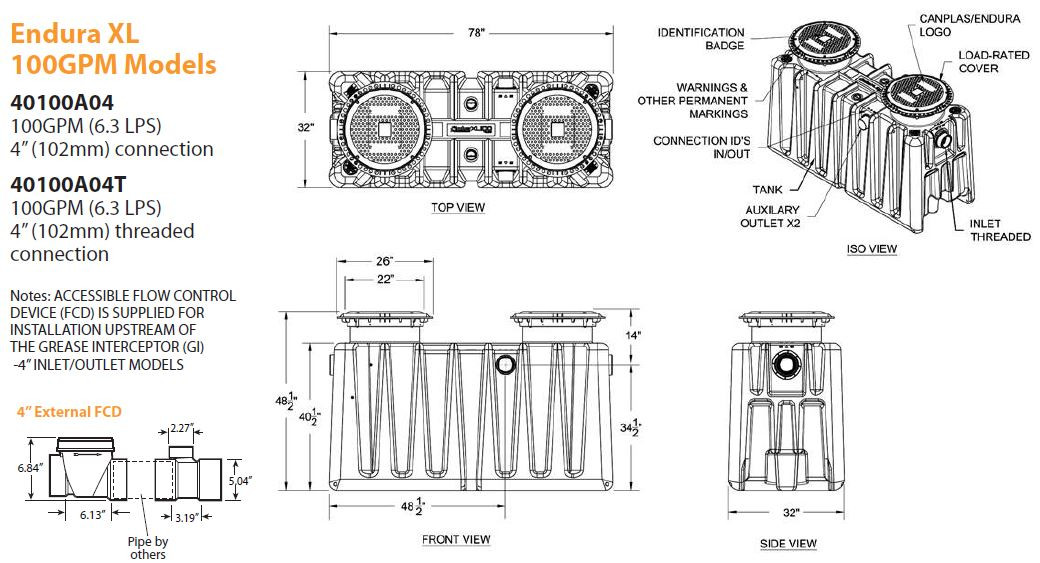

Endura XL Grease Traps

Endura XL Grease Interceptor 100 GPM

- SKU:

- HGI-100-04

- Availability:

- This product ships FREE via LTL to lower 48 states. Not available outside the USA.

- Shipping:

- Free Shipping

Description

Flow Management

Flow Management

Endura XL is a Hydromechanical Grease Interceptor (HGI). Unlike traditional, large capacity Gravity Grease Interceptors (GGI), our design uses more than just the natural buoyancy of fats, oils and grease (FOG) to separate them from waste water. This results in qualified efficiency based on National performance standards to ensure the most effective removal of grease.

Solids Retention Area

Passing over the ramp, any solids or debris separate by gravity into the defined solids retention area. This significantly reduces the likelihood of grease laden particles from exiting the interceptor.

Outlet Well Features

With FOG and solids having been effectively separated, the waste water leaves the tank via our uniquely enclosed outlet well, the effluent being discharged to the downstream drain through one of three pre-plumbed tank outlets.

Highlights:

1058 LB Capacity and 98% Efficiency

- Dynamic Inlet Baffle - Internal flow Control (Supplied Standard)

- Optional External flow control (PDIG101)

- Seamless Tank - Rotationally molded using up to 100% re-compounded material

- Dual Access Covers - Traffic Rated (CSA B481.1 Type 'S') Rated in excess of 20,000lb

- Airtight/Watertight cover, frame and adjustable riser system

- 18" Riser and 35" Riser Extensions available

- Limited Lifetime Warranty

- Please note that this product ships via LTL, only to commercial locations. Please contact us with questions. We only ship this to lower 48 states.

Specs

- Flow Rate (GPM): 100

- Flow Rate (L/Sec): 6.31

- Capacity: Lbs (MIN) 200 / Kg (MIN) 91

- Capacity (Actual - ASME A112.4.3): 1080 Lbs / 480 Kg

- Solids Capacity Lbs (Kg) estimated: 350lbs (118kg) 60 Gallons

- Average Efficiency % (ASME A112.4.3): 99%

- Operating Temperature Capabilities (Intermittent discharge): 160° F (71°C)

- Unit Weight Capacity (Empty): 283 lbs (128 kgs)

- Liquid Capacity: 257 gal (973L)

- Connection size (mechanical): 4"

- View and download CAD Drawings and Submittal Sheets

Cover Options

- Heavy Traffic Area Covers - S-Rated Traffic Access Covers (up to 20,000 LBS)

- Pedestrian / Light Traffic Covers - M-Rated Traffic Access Covers (up to 4,000 LBS)

- Cast Iron Access Covers - with 2 pry points and pick hole for easy removal. (Only available with hub connection model)

Brochures and Spec Sheets

Drain-Net XL Grease Interceptor Brochure

Drain-Net XL 100 GPM Grease Interceptor Spec Sheet

View and download CAD Drawings and Submittal Sheets

Drain-Net Comparison Sheet to other brands

Frequently Asked Questions:

Do Drain-Net XL Tanks need to be directly vented?

The practice of venting a grease interceptor directly is typically related to Gravity Grease Interceptors (GGI). Unless specifically mandated by local code or bylaw, with no variance allowed, a Hydromechanical Grease Interceptor (HGI) DOES NOT require the tank to be directly vented. Venting is, however, required on the downstream drain the same as most plumbing appliances; fixtures should allow effective and unrestricted discharge of effluent.

Do I need to install a clean out before or after an interceptor?

Most plumbing codes require an upstream and downstream cleanout immediately before and after the interceptor. This is good practice and gives positive indication of which outlet is in use.

Do I have to install the Flow Control Device?

For an HGI, the Flow Control is ESSENTIAL to the high performance operation of the interceptor. It must be installed as indicated and without it the interceptor is no longer meeting the requirements of its appropriate approvals. This is not acceptable to the AHJ and they should be asking for the installation to be rectified before approval is granted.

How do I size a Grease Interceptor correctly?

A grease Interceptor can be sized using two primary methods

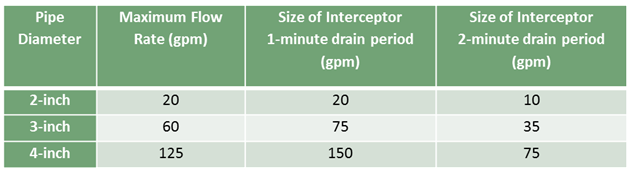

1. Flow Rate – When sizing by Flow Rate there are two sub sections

Fixture Capacity: Most commonly used method for Hydromechanical Grease Interceptors this looks at the maximum capacity of fixtures connected to the interceptor and the time taken to discharge that volume of wastewater through the interceptor. Units are expressed in Gallons Per Minute (GPM).

Calculation takes 75% of maximum capacity of all fixtures and based on a 1 or 2 minute period of time taken to discharge, results in a gallons per minute flow rate. This number is rounded up to the next available size of interceptor, i.e. 16.7gpm become a 20 GPM Grease Interceptor.

1. Pipe Size:

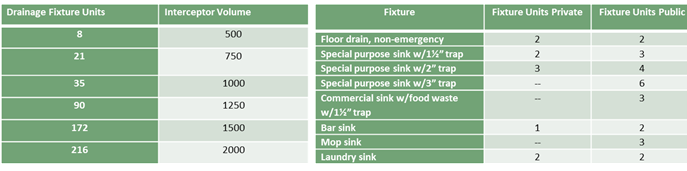

2. Capacity

Based on the volume of wastewater capacity (gallons) of the interceptor based on discharge fixture units (DFU’s) entering the interceptor

DFU’s are identified in Uniform Plumbing Code Ch.7 based on occupancy or use.

My jurisdiction requires Effluent Sampling via a downstream access. What do I do?

As an HGI approved to National performance Standards, although common for GGI (Concrete, Steel) Drain-Net XL DOES NOT typically require a separate sampling location. For those jurisdictions that do require the capability to sample, Drain-Net XL incorporates a sampling port within the outlet assembly (sold here). This is accessed by the simple removal of the air balance/sample port cap allowing water quality samples to be taken for analysis.

How often should an interceptor be cleaned?

Cleaning of an interceptor is a case by case situation. Each facility will have many different factors impacting need for maintenance and cleaning. A licensed contractor will have the experience and equipment necessary to help establish the right schedule of maintenance for your facility. How much will it cost to maintain my Drain-Net XL installation?

In terms of comparison Drain-Net XL units are significantly more compact (less internal volume) than their equivalent Gravity counterparts. As pumping is typically charged by the volume of gallons removed the ongoing maintenance will be proportionally less as well. Rates will vary significantly by region and by contractor. Always use a licensed or approved contractor to maintain your interceptor.

What can be connected to an interceptor in respect of wastewater discharge?

A grease interceptor UNDER NO CIRCUMSTANCES will receive sanitary wastewater discharge – i.e. that from WC flushing for example.

Wastewater discharge to a grease interceptor will be from foodservice activities only, its application being to separate non petroleum Fats Oil and Grease from waste water.

The requirements for appliances and fixtures that must and must not be connected to a grease interceptor is typically defined by your local plumbing codes and or jurisdictional by-laws. You should consult a licensed plumbing professional or your local city plan check.

How does a compact HGI replace the function of a 1000 gallon concrete tank?

A Gravity Grease Interceptor (your typical concrete tank) will be sized on capacity and therefore typically a number between 750 gallons and 1500 gallons is commonly seen. This number can however be substantially higher based on local requirement or application. In most jurisdictions, a method called the 25% rule is employed as the means to indicate or mandate the cleaning frequency. The 25% is the percentage of the total working volume of the interceptor which can be occupied by a combination of Fats , Oil and Grease and Food Solids.

For example: A GGI tank with a capacity of 1000 gallons can only function to a point where 250 gallons (1000 X .25) of its volume is occupied by solids and grease. That equates to approximately 1090 lbs of grease. If we assumed that 100 gallons of this is the solid material, that leaves 150 gallons of grease capacity before cleaning is “required”. On average this translates to approximately 8-10 weeks on average.

Now compare that to an XL100 HGI. Based on the independent third party testing to determine qualified performance & efficiency, the Drain-Net XL100 has a significantly smaller 257 gallon total capacity, but a qualified efficiency exceeding 95%. This translates to essentially the same grease capacity as the GGI, exceeding 1000 lbs of functional grease capacity.

I heard that plastic tanks can float in high water table areas, particularly when pumped down for cleaning.

Is this true?

Yes it is, however Drain-Net XL is specifically designed to address this challenge. If you look at XL tanks from the end you will see that the top is wider than the bottom and that there are along the sides corrugations that are closed toward the bottom of their profile. This profile is the reverse of an ice cube sitting in a freezer tray. Typically some upward force is applied around or beneath the ice cube and out it pops! Now reverse that principle to the form of the tanks – the broad base not only provides stability but also has substantial resistance to being force upward by water or freeze-thaw action. This in conjunction with the closed corrugations positively captures the tank in the excavation once backfilled. For areas of particular concern in addition an 8” concrete slab can be poured around the base to introduce further resistance. Provision is also made for the use of ground anchors or alternates that will need to be specified locally by an engineer respective of local ground conditions.

Can I install more than one Drain-Net XL unit if my jurisdiction needs a minimum capacity by code?

In Principal, yes you can. It will be necessary you contact your plan check or review team at the authority having jurisdiction and have your engineer submit a proposal based on the information provided.

Useful Terms and Definitions

- HGI – Industry abbreviation for Hydromechanical Grease Interceptor. By definition an HGI is designed to use managed flow, air entrainment and specifically designed features to provide an enhanced level of separation efficiency, removing non petroleum FOG (Fats, Oil and Grease) from a transition flow of waste water, generated by commercial foodservice activities (Restaurants, Cafeterias, Institutional Kitchens , Sandwich Shops and Coffee houses for example). HGI’s are performance tested for efficiency of grease separation based on National Standards.

- Operational Cost Index =1

- GGI - Industry abbreviation for Gravity Grease Interceptor. By definition a GGI has a minimum of 350USG capacity and in operation 500USG to 1500USG of capacity are most common. No flow control device. Separation of FOG is based on capacity and retention time of water (minimum 30 mins to exchange volume). At this time no performance Standards are published for GGI’s.

- Operational Cost Index = 5-10+

- GRD – Industry abbreviation for Grease Removal Device. Designed firstly as an HGI, a GRD uses a heat source and a timed or sensor based skimming (or draw-off) device to remove accumulated FOG from the separation chamber into an external container for collection and disposal. These units require daily maintenance for management of food solids.

- Operational Cost Index = 2.5 - 5

- Cost Index: A way of indicating the relative cost of different types of interceptors to each other for broad comparison purposes. This includes product purchase, installation cost and typical maintenance.

- Air Entrainment: Mixing of air with Influent using a flow control device. Air and grease are attracted to each other, the air wanting to separate from water more easily than grease. Because they become mixed together the air increases the efficiency of separation.

- Effluent: Waste water containing little to no FOG, being discharged out of the interceptor.

- Influent: Waste water containing uncontrolled and variable levels of FOG based on the nature and practices of the foodservice operation.

- Separation Chamber: Zone inside the interceptor where grease separates from water and is retained.

Additional Information

Important Shipping Info: |

This product ships FREE via LTL to lower 48 states. Please call if you would like a shipping outside the lower 48. |